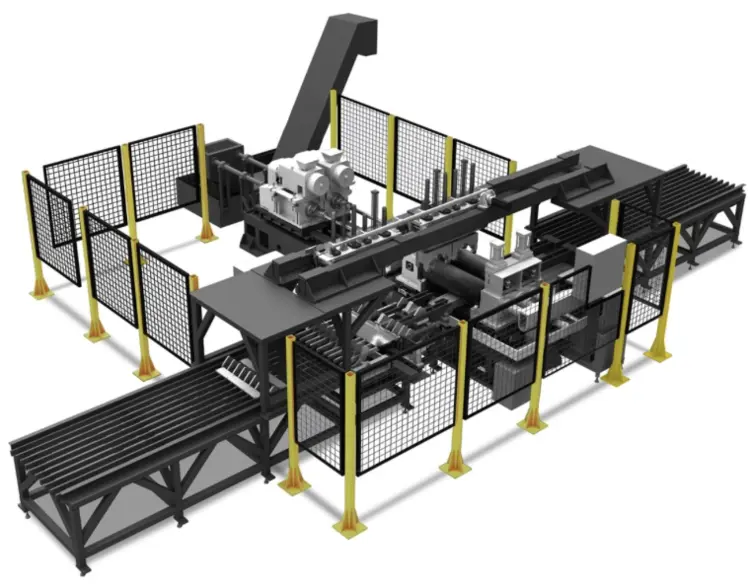

Precihole Machine Tools offers customized deep hole drilling special purpose machines for deep hole drilling and hole finishing applications. We have experience in manufacturing machines for over 150 special applications in various industries where the requirements did not fit any of our standard machines. We have supplied more than 400 machines that are currently being used by large and medium scale industries around the world. These machines are capable producing high production volumes, feature multi-spindle and multi-axis capabilities, and can be fully or semi-automatic. Tooling and work holding are provided to accommodate your component. Our team of highly experienced engineers works closely with customers to define requirements, study the underlying process, come up with a concept, then design, manufacture and prove out the machine. Every special machine undergoes thorough testing on the floor before dispatch to ensure smooth working in production mode. Professional training, documentation and process engineering are all provided to successfully adapt the machine onsite. The following machines have been “made-to-order” for our customers worldwide:

Twin spindle BTA drilling machines with auto loading and unloading

Multi-axis BTA drilling machines

Twin spindle gun drilling machines with independent spindles

Ejector drilling machines for automotive crankshafts

Twin spindle counter boring machines for shocker bodies

Machine features:

High production machines

Automatic loading and unloading

Fuzzy logic

CE certified

Customers worldwide include:

Schoeller Bleckmann

Austria Tubacex Group (Spain)

Ratnamani Metals & Steels (India)

Cummins

Mahindra

Sona

Sundaram Fasteners Ltd.

Kobelco

Nuclear Power Corporation of India

Munjal Showa

TATA

Walchandnagar

Komatsu

Eldorado Tool – Drill Masters

Rane – TRW

Xact Specs Precision Machining

Delphi – TVS Diesel Systems Ltd.

Chassis Brakes International

WellDynamics

RMG Alloy Steel Ltd.

IMG Gears

Larsen & Toubro Ltd.

Namenska

Parker

General Electric

Sensortech Saudi

Ingersoll Rand

Bosch

Zastava Arms

Sebros

Bill Forge

Honda

Mico Bosch Group

Faxon Firearms

Drilling Diameter Range 25mm – 80mm

Drilling Depth 320mm – 950mm

Component Billets

Component Material Alloy Steel, SS, Duplex

Component Diameter 180mm – 350mm

Component Loading / Unloading Automatic

Number of Spindles 2

Chip Collecting System Scraper Type Conveyor

Spindle Motor 39 kW per Spindle

Coolant Tank Capacity 7,500 Liters

Total Connected Electric Power 275 kW

Spindle Speed 150 – 1,300 RPM

Feed Rate 20 – 400 mm/min.

Rapid Traverse Rate 5,000 mm/min.

Machine Footprint 11,200 x 6,800 sq. mm

We use cookies to improve your experience. Privacy Policy.