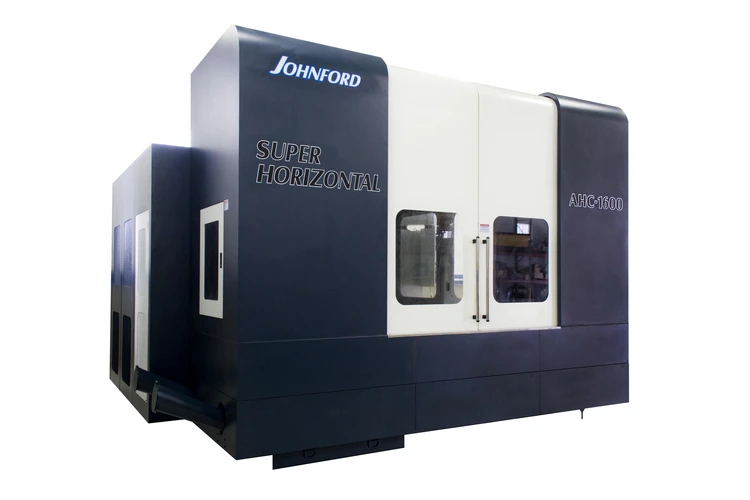

The Johnford AHC-1600 moving column table-type horizontal machining center is ideal for aerospace applications as well a wide variety of other industries. The machine features a moving column for the Z axis and a moving table for the X axis. The design provides maximum rigidity and accuracy as well as full support of the table over the complete X axis travel. The X axis is fully supported by the base with absolutely no overhang, eliminating any need for outriggers or outboard supports to handle high table loads. With standard accessories, the rigid Meehanite cast iron machining center weighs in at more than 40,000 lbs.

The AHC-1600 features precision-ground and induction-hardened box ways in the X, Y, and Z axes. All mating surfaces are coated with Turcite-B and hand scraped for fit. A pressurized automatic oil system force lubricates the ways. Large (2.0″/50 mm)-dia., pre-tensioned ballscrews and powerful servo motors achieve accurate positioning. Standard Heidenhain linear scales in all linear axes assure consistent accuracy.

The standard 6,000 rpm 50-taper spindle has a 35 hp main motor and 2 speed gear drive. The spindle and gearbox are oil cooled for minimal thermal growth. Spindle options include 10,000 rpm direct drive 50-taper spindles and a high power 15,000 rpm HSK-100A spindle that provides 56 hp and 300 lb-ft of torque.

A stand-alone heavy-duty 40-tool arm-type automatic tool changer is standard, with 60, 80 and 120 tool capacity optional. Also standard is a comprehensive chip removal system, a high volume coolant system, full machine enclosure, and a combination 63″ x 32″ flat table with a built-in 800mm full B-axis rotary table. The standard Fanuc OiM-D control is suited for all types of machining applications up to 4+1. An optional Fanuc 31iM-B control handles more demanding high speed machining applications as well as 5 axis simultaneous contouring.

Travels

Longitudinal Travel (X) Axis 63" (72”, 79”, 118” opt.)

Vertical Travel (Y) Axis 50”

Column Travel (Z) Axis 40"

Spindle center to table top 5.5” – 55.5”

Spindle nose to table center 7.9" min / 47.9” max

Table (Combination)

Flat Table Working Surface 63" x 32" (72”, 79”, 118” length opt.)

Rotary Table Diameter 31.5”

Maximum Workload on Flat Table 10,120 LBS.

Maximum Workload on Rotary Table 4,400 LBS.

Table Surface Ground / T-slotted

No. of T-slots x Width 7 x 22mm

Spindle (Standard)

Spindle Motor 35 HP

Spindle Torque 575 ft/lbs at only 375 RPM

Spindle Taper ISO-50

Spindle Drive System 2 speed gear box

Spindle Speed 0-6000

Spindle (Optional Inline Direct Drive)

Spindle Motor 35 HP Fanuc (40HP opt.)

Spindle Torque 122 ft/lbs at 1500 RPM

(258 ft/lbs at 500 RPM optional)

Spindle Taper ISO-50

Spindle Drive System Direct Drive

Spindle Speed 0-10000

Spindle (Optional Weiss Integral Motor Spindle)

Spindle Motor 56 HP high torque

Spindle Torque 300 ft/lbs @ 1000 RPM

Spindle Taper HSK-100A

Spindle Drive System Integral Motor

Spindle Speed 0-15000 RPM

Automatic Tool Changer (arm type)

Number of Tools 40 tools (60, 80, 120 opt.)

Tool Selection Bi-directional-random

Tool Change Time 6 sec. tool to tool

Maximum Tool Diameter 4.9" with adjacent tools, 9.8” without

Maximum Tool Weight 33 LBS

Tool Type CAT-50 (BT-50 / HSK-100A opt)

Maximum Tool Length 15.7"

Ballscrews and Axis Motors

X-Y-Z Ballscrew Diameter 2.0” X, Y, Z x 10 pitch

Ballscrew Type Class 3 double nut pre-loaded

Ballscrew Mounting Type Pre-tensioned

X-Y-Z-B Servo Motor HP 9.0 - 5.2 – 9.0 - 5.2HP

Servo Motor Mounting Direct coupled XYZ

Feeds

Rapid Traverse Rate X,Y,Z 590 IPM

Rapid Traverse Rate B axis rotary table 11.1 RPM

Cutting Feed Rate 0.01 - 472 IPM

Linear Positioning Accuracy +/- .0003" full stroke

Linear Repeatability +/- .0002"

B axis Positioning with / without scale 5 arc seconds / 15 arc seconds

General

Coolant Tank Capacity 120 gallons

Machine Weight (base machine only) 44,000 LBS (63” X axis)

Floor Space 171" X 170" x 122" (63” X axis)

Machine Power Source 208/220 Volts, 3 Phase 150 Amps**

Air Source 90 PSI

Standard Machine Accessories

Flood Coolant System with programmable air blast

Air blast for spindle

Auto Lubrication with Alarm

Automated chip removal system with 4 screw type chip conveyors

Halogen work lamp

2 speed geared head with spindle / headstock cooler

Remote Handwheel

Heat exchangers for control cabinets

Hydraulic counterbalance for headstock

Rigid Tapping

B axis rotary table (.001 degree)

40 Tool ATC

We use cookies to improve your experience. Privacy Policy.